Rectification of cutting blades before coating

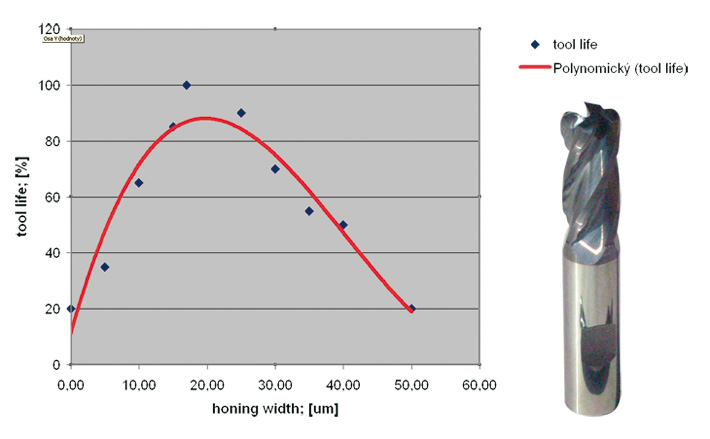

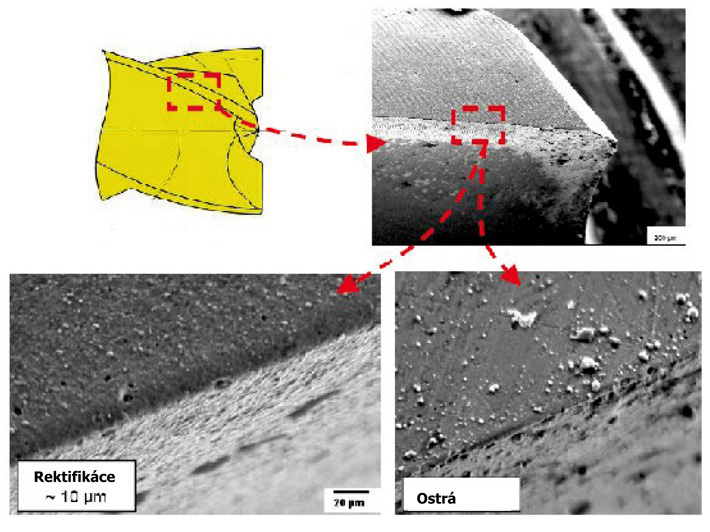

Our company offers a new technology of cutting blade preparation to coating – rectification. The process of rectification is performed in an automated cycle with the tool blasted in a special polishing medium for controlled rounding of the tool edges. The process removes potential imperfections of the cutting edge, and improved roughness and thus usable properties. Tool damage (destruction) is excluded. Controlled rectification (rounding) of the blade edge is able to achieve:

- Improved coat adhesion

- Overall extension of the tool life

- Stabilisation of cutting edge durability

- Minimisation of blade chipping

The size of rectification depends on the type of the worked material and the technological operation. This operation is recommended to be performed with hard metal tools for machining hard, abrasive materials (cast iron, tool steels, bearing steels). The same machine can be used for tool polishing (removal of macro particles) after coating. The operation of polishing after coating can be recommended for deep drilling above 5xD, and milling with TiAlN, AlTiN coats.